Magenta Production Site

The Parola e Luraghi S.r.l carries out foundry activity for the production of cast iron castings for the main industrial sectors (mechanics, tractors, industrial vehicles, earthmoving machinery, railways), with a production capacity of 60 tons/day.

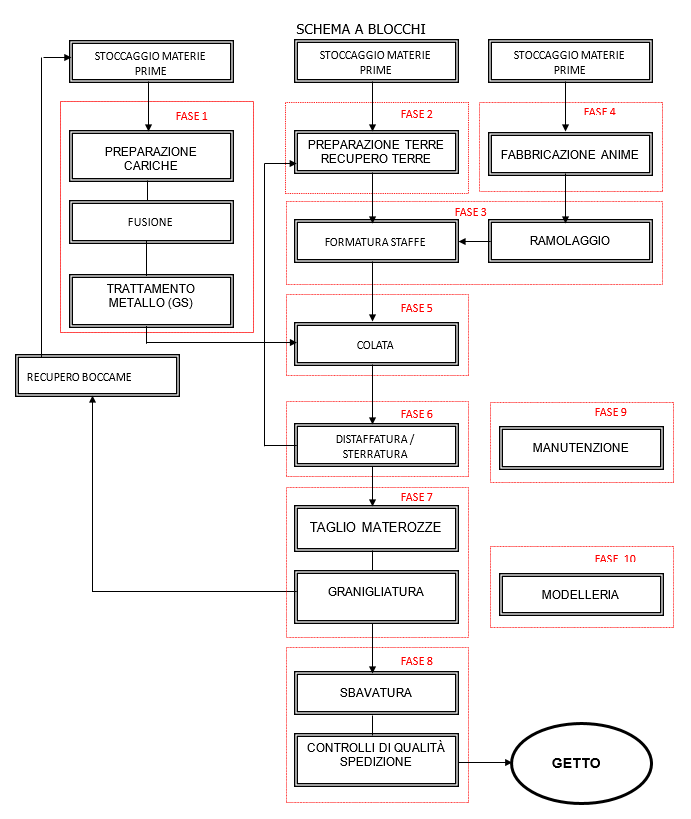

The production process in place follows the typical phases of the foundry activity:

- Melting by oxy-methane rotary furnaces

- Sand preparation

- Forming of the forms

- Preparation of moulds

- Casting

- Shakeout

- Deburring

- Quality Control

- Storage and shipping

Since its foundation in 1921, the company has been based in the Municipality of Magenta (MI), in an area classified as industrial, surrounded by residential and agricultural areas.

Over the years, the plant located in Via Dante, built in 1951, has been modified and expanded with state-of-the-art systems, technical and design offices and jet simulation facilities, as well as a metallographic and radiometric laboratory and a new wing dedicated to the deburring and finishing and a warehouse department for the shipping of materials.

Numerous acoustic mitigation and environmental improvement interventions have been carried out.

In 2003, the area of Via Dante was upgraded with new technical-commercial offices, administrative management offices and a wing dedicated to workers’ facilities (lavatories - changing rooms - canteen services).

In this production site in Magenta, gray and ductile iron castings of all shapes and medium and large sizes are produced with the use of a "Belloi" horizontal automatic system and the hand-operated department, allowing the casting of pieces up to 3000 kg. in weight.

Further improvements have taken place starting from 2018, when three machines have been added in the Cold box core forming department, some strategic auxiliary systems have been replaced (jet handling belt, Vibroprocess casting unloading machine and exhaust system, Andromat manipulator); in addition to this, a new Omsg sandblaster was installed and the lining machines were replaced through the installation of new specific overhead cranes for the handling of molten material.

An expansion of the hand bracket storage area has also been implemented after casting, creating a second bracket storage line next to the already existing one.

In 2024, starting from June, the new deburring department was built, with the complete renovation of the transformer room.